November’s Tools of the Trade come to us from the village of Hurstmonceux, home to The Royal Sussex Trug Company. For nearly two hundred years this small village on the high weald has been home to generations of trug makers, crafting their willow and chestnut baskets in the same manner as Thomas Smith, the original Sussex Trug maker.

The traditional ‘trog’ had been used since Anglo Saxon times for storing and measuring grains and liquids, but these medieval vessels were made with solid timber and were heavy and cumbersome. Thomas Smith reinvented the trog as the trug, using Sweet Chestnut and Willow to make a basket which was light yet strong. There was an immediate demand for Smith’s trugs, and he quickly set up a workshop to supply the demand from houses and gardens throughout the country.

But it was the 1851 Great Exhibition that made the Sussex trug famous. Queen Victoria saw Thomas’s trugs and ordered some as gifts for members of the Royal Family. Thomas made the trugs personally and and then he and his brother walked the 60 miles from Sussex to Buckingham Palace to deliver them. The Queen was suitably impressed and bestowed her Royal Warrant on Smith - hence the Royal Sussex Trug.

There are a handful of trug makers still based in Sussex, but only one can trace its descent from Thomas Smith and the original Royal Sussex Trug. Robin Tuppen, proprietor of the Thomas Smith Trug Shop explains the tools and the process involved in the manufacture of a trug:

“The two tools we supplied were a draw knife and a cleaving axe (also known as a froe). The cleaving axe is used to split the chestnut that we use to make the handles and rims of the Royal Sussex Traditional Trugs.”

“The Cleaver uses a special axe, which is placed on top of the Sweet Chestnut pole (also known as a cooper pole or a Trug Bat) and this is hammered in with a wooden maul (also made of Chestnut). He then works the axe through the length of the pole, using the natural grain of the wood to split it in two. These halves are then cleaved again to produce smaller sizes which then go on for shaving as handles and half rims.”

“The Royal Sussex Trug handles and rims are shaved by the Craftsman on a “Shaving Horse”. The draw knife is used to shave them down to the correct thickness and width.“

"There are many different shapes and sizes to remember and the Craftsman has to do all this work by eye alone. The wood is then ready for steaming.”

“Any wood left over from the making process is burned on a wood fired boiler to raise steam to soften the chestnut for bending. We use our wood to fire our boilers because, when wood is burned, it gives off no more carbon dioxide than the tree from which it came absorbed during its lifetime. Truly carbon neutral! The chestnut is placed into the steamer, around which steam circulates freely (not under pressure), thus making the Chestnut pliable. It is then bent round the “former” to make the handle or rim.”

“The Craftsman has only a few seconds to do this before the wood becomes stiff once again, so he has to be quick as well as skilled. The handles and rims are then nailed together to make the “frames”, which are then sent to the Maker to have the boards placed inside them.

"Assembling the trug is done sitting on a “Making Horse”. The Craftsman receives the frame and fixes the boards into it. The boards, made from re-cycled Cricket Bat Willow are also steamed and are then bent on the ends in the Steam Shop before being sent to the Maker. This makes them springy and stops them splitting when they are shaped within the frame. The boards are placed inside the frame and fixed securely into position using solid copper tacks.”

“Once the Trug is made, the legs are nailed on to the bottom and the Trug is then ready to go for the final quality inspection before being signed by the craftsman, stamped and given a unique reference number on the bottom before being despatched.”

Robin and his team make over 100 different shapes and sizes of trug, and their uses are limited only by your imagination. Our trug, however, is the perfect size for use in the home or garden - and it has the all-important stamp and signature on the bottom, proving that it is the original Royal Sussex Trug.

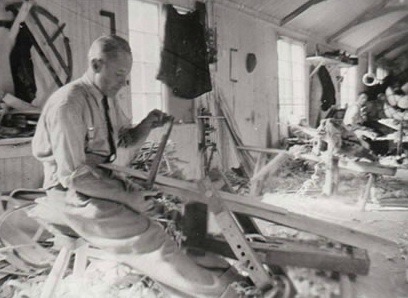

Albert Jenner making a trug for R.W Rich, another local manufacturer of Sussex trugs.

Bill Dooley sat on his making horse, shaving the chestnut with his draw knife.

Eddie Smith, last of the Smith owners.

Hazel Pilbeam finishing a Royal Sussex Trug.

Our thanks to Robin and all at the Thomas Smith Trug shop for their photographs and information. Sussex Trugs are available online and in store now.