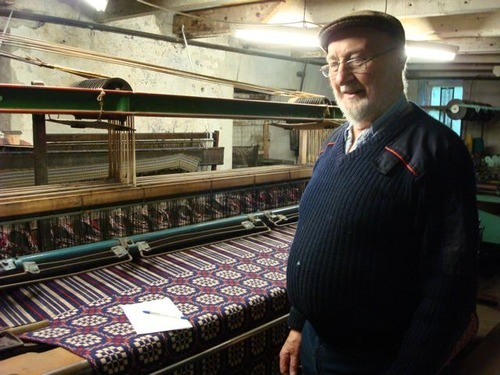

With a new and exclusive petrol blue colour on offer, we felt it was time to give a little back story to our Welsh tapestry blankets.... We work with one of the last remaining working woollen mills in West Wales which has a history dating back over 125 years. For the past 35 years it has been run by Mike and his family. And Mike is the best man to tell us about his tools and processes:

We work with one of the last remaining working woollen mills in West Wales which has a history dating back over 125 years. For the past 35 years it has been run by Mike and his family. And Mike is the best man to tell us about his tools and processes:

We have sold these beautiful blankets for many years at Labour and Wait. We source vintage and antique blankets from all over Wales, and we never fail to be astounded by the brightness and variety of the colours. However, as their popularity has increased, so has their price, and it becomes harder to find the spotless - and the mothless - examples we are looking to sell. So we were very pleased to work with Mike and his mill producing high quality modern versions.

At the moment we sell the blanket in red, natural, gold, green and petrol blue; with a orange pattern in the works, which remain exclusive colourways to Labour and Wait.

“The cone of red yarn is a sample of dyed yarn used to make our Welsh tapestry bedspreads. It is a blend of 100% pure new English wools spun specially for us by a long established firm in Huddersfield. It is then sent onto Bradford where it is dip-dyed using well established traditional methods.”

“The natural yarns used in our tapestries are from Wales and are, of course, the natural colour of the fleece with no dyeing involved.”

“Did you know that 7 miles of yarn is required to make 1 double size bedspread, and in doing so the threads will cross over each other 5.3 million times. WOW.”

WOW indeed, Mike. It sounds like a lot of work, but at least we have something wonderful to show for it.

Our thanks go to Mike for showing us the mill, and for revealing the intricacies of the Welsh tapestry blanket.